The Future of CNC Machining: Trends and Innovations

Introduction to CNC Machining

CNC machining, or Computer Numerical Control machining, has revolutionized the manufacturing industry by providing precise and efficient production processes. As technology continues to advance, CNC machining is evolving with new trends and innovations that promise to further enhance its capabilities. In this blog post, we'll explore some of these exciting developments and what they mean for the future of CNC machining.

Automation and Smart Technology

One of the most significant trends in CNC machining is the integration of automation and smart technology. Modern CNC machines are increasingly equipped with advanced sensors and connectivity features that allow for real-time monitoring and adjustments. This not only improves accuracy but also reduces downtime and increases productivity.

By leveraging the Internet of Things (IoT), CNC machines can now communicate with other devices and systems, enabling a seamless flow of data across the production line. This connectivity supports predictive maintenance, whereby machines can alert operators to potential issues before they become critical, thereby minimizing disruptions.

Advancements in Materials and Tools

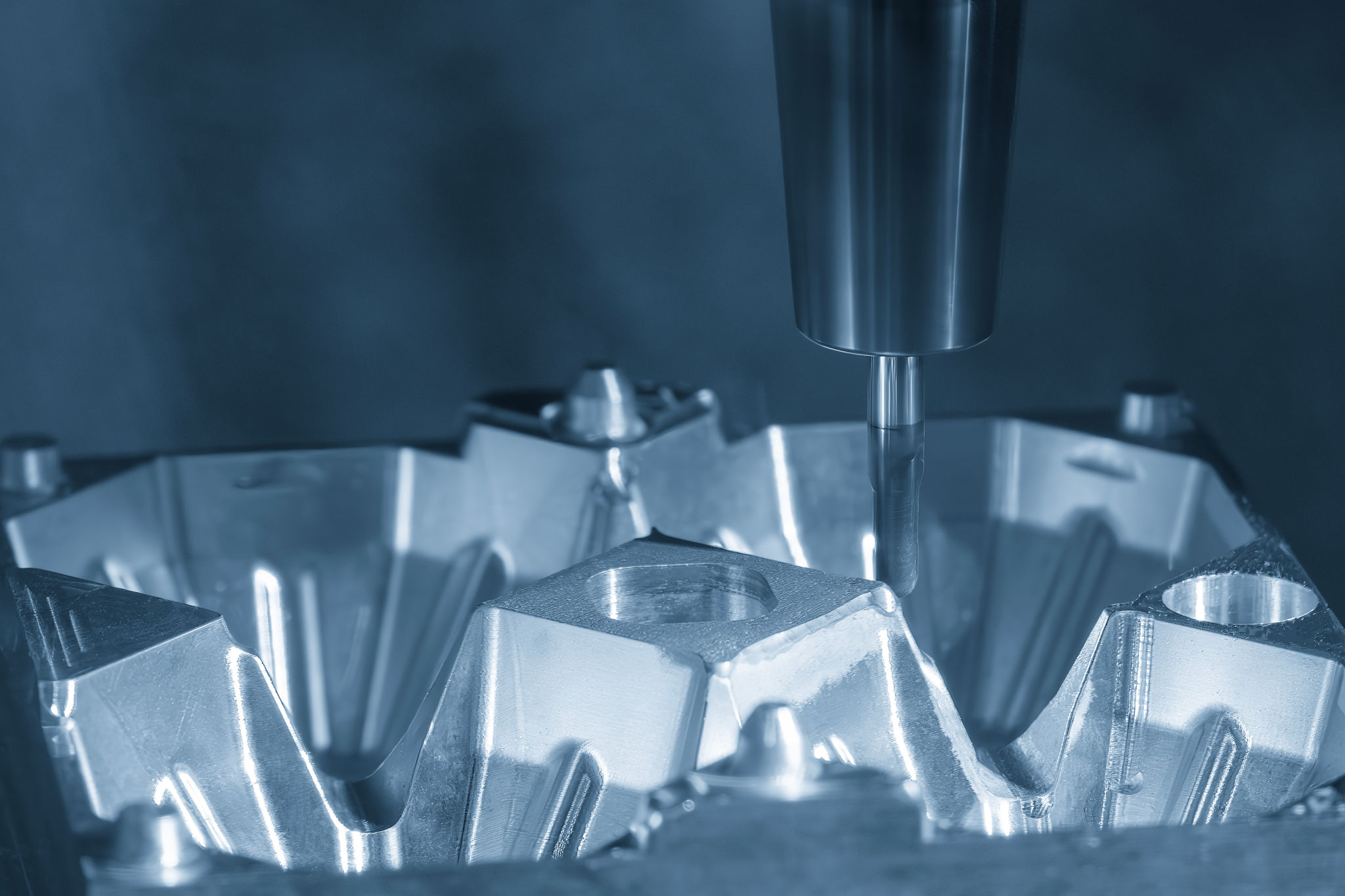

The development of new materials and cutting tools is another area where CNC machining is seeing significant innovation. With the introduction of harder and more durable materials, manufacturers can now produce parts that were previously difficult or impossible to create using traditional methods.

Moreover, advancements in tool coatings and geometries have extended tool life and improved cutting performance, allowing for faster production times and lower costs. As these technologies continue to evolve, we can expect CNC machining to deliver even greater precision and efficiency.

Sustainability in CNC Machining

As industries worldwide strive to become more environmentally friendly, CNC machining is no exception. Manufacturers are increasingly focusing on sustainability by reducing waste and energy consumption. One approach is through the use of recyclable materials and more efficient machining processes that minimize scrap.

Furthermore, innovations such as dry machining, which eliminates the need for cutting fluids, are gaining traction. These advancements contribute to a more sustainable manufacturing process, aligning with global efforts to reduce carbon footprints.

Customization and Flexibility

The demand for customized products has led to a shift towards more flexible CNC machining solutions. Advanced software allows manufacturers to quickly adapt their machines to produce small batches or unique parts without extensive retooling. This flexibility is crucial in industries like aerospace and healthcare, where bespoke components are often required.

Additionally, the rise of additive manufacturing, or 3D printing, has encouraged a hybrid approach where CNC machining is used in conjunction with additive processes to create complex geometries efficiently. This synergy between technologies opens up new possibilities for innovation in product design and manufacturing.

The Role of Artificial Intelligence

Artificial intelligence (AI) is playing an increasingly important role in CNC machining. AI algorithms can analyze vast amounts of data to optimize machining processes, predict tool wear, and even suggest improvements. This enhances decision-making capabilities, allowing manufacturers to achieve higher levels of precision and efficiency.

Machine learning, a subset of AI, enables CNC machines to learn from past operations and continuously improve their performance. As AI technology becomes more sophisticated, its integration into CNC machining will likely lead to even greater advancements in automation and production quality.

Conclusion

The future of CNC machining is bright, with numerous trends and innovations poised to transform the industry. From automation and smart technology to advancements in materials and sustainability, these developments promise to enhance precision, reduce costs, and increase efficiency. As manufacturers continue to adopt these innovations, CNC machining will remain at the forefront of modern manufacturing, driving progress across various sectors.