Step-by-Step Guide to DIY Machinery Repairs

Understanding the Basics of Machinery Repairs

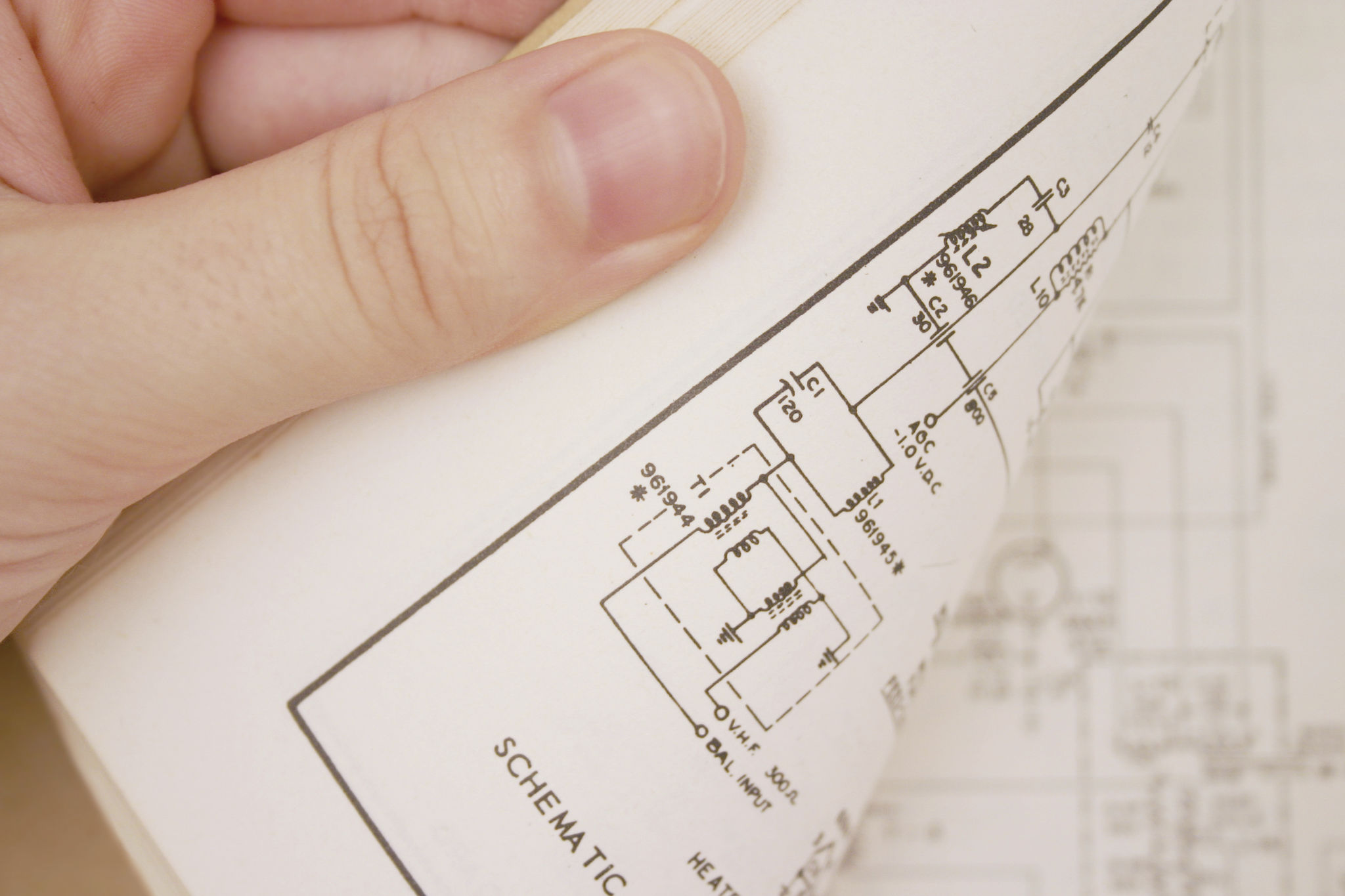

DIY machinery repairs can be a rewarding and cost-effective approach to maintaining your equipment. Before diving into the repair process, it's crucial to know the basics of how your machinery operates. Familiarize yourself with the user manual and understand the different components and their functions. This foundational knowledge will help you identify issues more effectively.

Gathering the Necessary Tools and Parts

Having the right tools and replacement parts at your disposal is essential for any repair task. Create a checklist of tools you might need, such as wrenches, screwdrivers, and pliers. Additionally, ensure you have the appropriate replacement parts for your machinery model. This preparation will save time and reduce frustration during the repair process.

Diagnosing the Problem

Identifying the problem is the first step in any repair. Start by observing any unusual sounds, leaks, or performance issues. Use diagnostic tools if available, and refer to the user manual’s troubleshooting section. Proper diagnosis is key to executing a successful repair.

Step-by-Step Repair Process

Once you've diagnosed the problem, it's time to proceed with the repair. Follow these steps to ensure a systematic approach:

- Disconnect the machinery from any power source to ensure safety.

- Carefully disassemble the necessary parts, keeping track of screws and small components.

- Replace or repair the faulty components as needed.

- Reassemble the machinery, ensuring all parts are securely in place.

- Test the machinery to confirm the issue has been resolved.

Safety Precautions

Safety should always be your top priority when performing machinery repairs. Wear protective gear such as gloves and goggles, and ensure your workspace is well-lit and free of hazards. Always follow the safety guidelines outlined in the user manual to prevent accidents.

Maintenance Tips to Prevent Future Issues

Regular maintenance can significantly extend the life of your machinery. Here are some tips to keep your equipment in top condition:

- Regularly clean and lubricate moving parts.

- Inspect components for wear and tear.

- Keep the machinery free of dust and debris.

- Schedule periodic professional maintenance checks.

When to Seek Professional Help

While DIY repairs can be effective, there are times when professional assistance is necessary. If the repair is beyond your skill level or requires specialized tools, contact a professional technician. Ignoring complex issues can lead to further damage and higher repair costs.

By following these steps and guidelines, you can successfully tackle DIY machinery repairs, saving both time and money while ensuring your equipment remains in optimal condition. Remember, a well-maintained machine is a reliable machine.