Precision Machining in Dalton: Why Quality Matters

Understanding Precision Machining

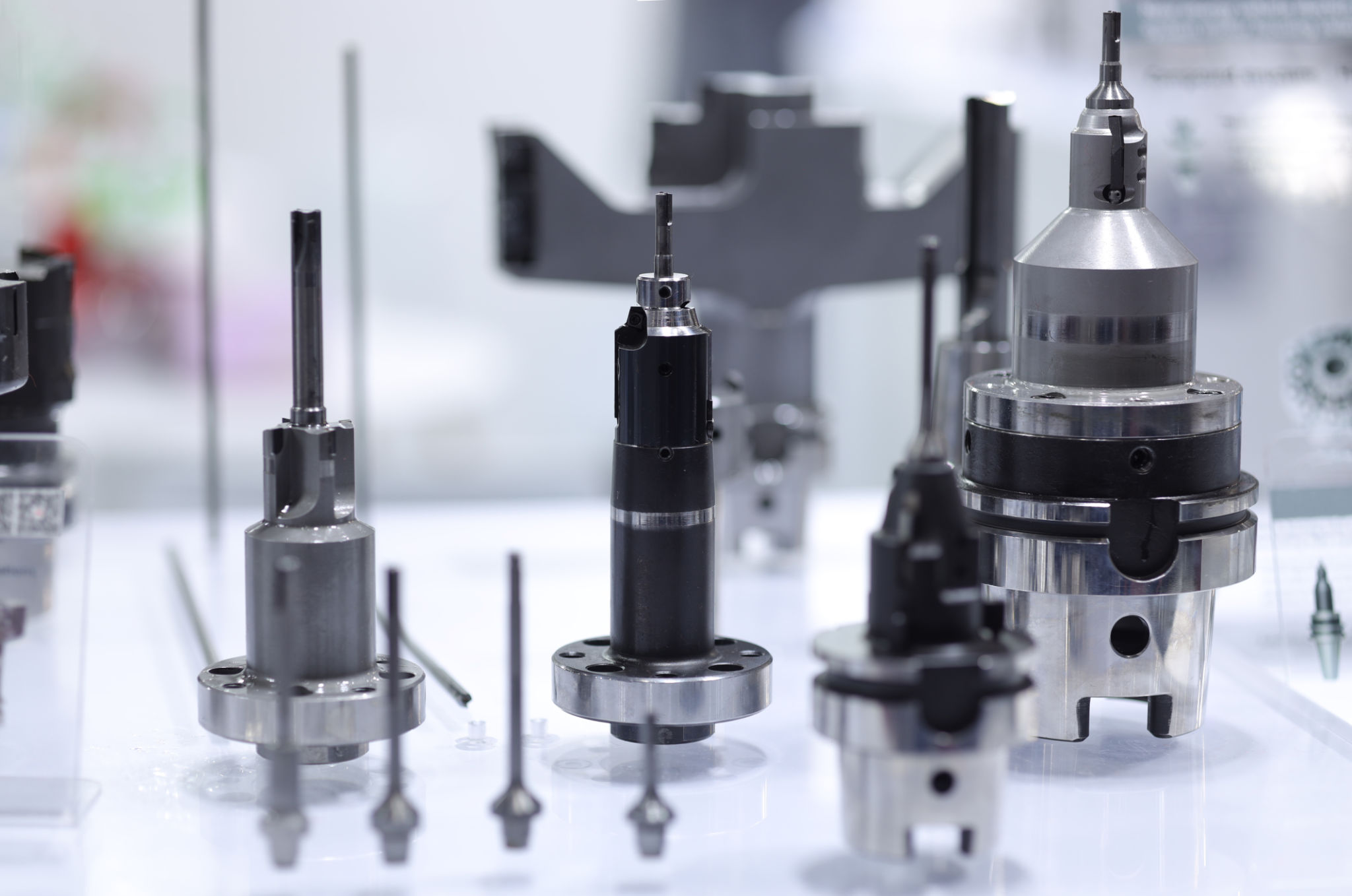

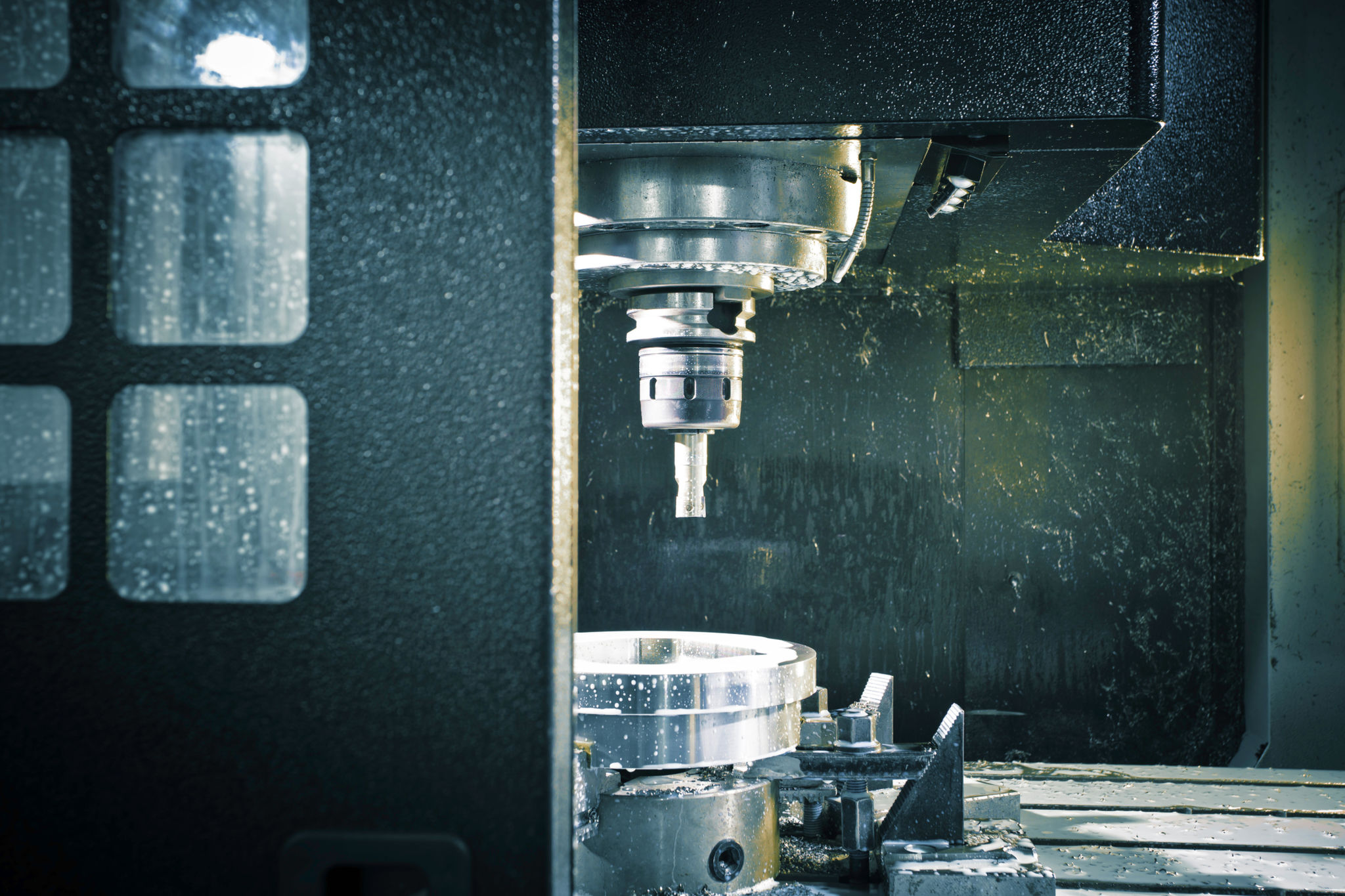

In the world of manufacturing, precision machining stands out as a critical process that ensures the creation of components with exact specifications. This technique involves removing material from a workpiece to achieve a desired shape and size, employing tools like lathes, mills, and grinders. The precision in machining refers to the level of detail and accuracy achieved, which is vital for applications where even the slightest deviation can lead to significant issues.

Dalton, known for its industrial prowess, hosts several facilities that specialize in precision machining. These establishments cater to industries ranging from aerospace to automotive, where quality and precision are non-negotiable. The demand for precision machining in Dalton is fueled by the need for high-quality components that meet stringent industry standards.

Why Quality Matters in Precision Machining

Quality is the cornerstone of precision machining. It ensures that parts are produced to exact specifications, which is crucial for the proper functioning of machinery and products. High-quality machining minimizes the risk of errors that could lead to product failures or safety hazards. In industries such as medical devices or aerospace, precision can be the difference between life and death.

Moreover, maintaining quality in precision machining enhances durability and performance. Components manufactured with high precision have a better fit and finish, which contributes to the overall efficiency and longevity of the machinery they are part of. This not only reduces maintenance costs but also enhances customer satisfaction.

The Role of Technology in Precision Machining

Advancements in technology have significantly impacted precision machining. Modern equipment equipped with computer numerical control (CNC) allows machinists to produce complex parts with unparalleled accuracy. These machines follow programmed instructions, ensuring consistency and reducing human error.

In Dalton, companies are investing in state-of-the-art technology to meet the growing demands for precision and quality. The integration of digital tools and software has streamlined processes, making it easier to achieve precise outcomes while optimizing production times.

The Importance of Skilled Workforce

While technology plays a crucial role, the expertise of skilled machinists cannot be overlooked. A well-trained workforce ensures that machines are operated efficiently and that any issues are promptly addressed. In Dalton, many companies emphasize training programs to keep their staff updated with the latest techniques and technologies.

A skilled machinist can make informed decisions that enhance productivity and ensure the final product meets quality standards. This combination of human expertise and technological advancement is what sets Dalton's precision machining industry apart.

Conclusion: Investing in Quality

The significance of quality in precision machining cannot be overstated. For businesses in Dalton, investing in high-quality equipment, skilled personnel, and cutting-edge technology is essential for maintaining a competitive edge. By prioritizing quality, these companies not only meet industry standards but also exceed customer expectations.

Ultimately, the commitment to quality ensures that precision-machined components perform reliably and safely across applications. As industries continue to evolve, the focus on quality will remain a driving force in the success of precision machining enterprises in Dalton.