Precision Machining Explained: How It Supports Tufting Parts Production

Understanding Precision Machining

Precision machining is a critical process in the manufacturing industry, renowned for its ability to produce parts with exceptional accuracy and tight tolerances. This method involves the use of advanced machinery and technology to shape raw materials into precise components needed for various applications. In the context of tufting parts production, precision machining plays an indispensable role, ensuring that every piece fits perfectly into the larger assembly.

By utilizing computer numerical control (CNC) machines, manufacturers can achieve high levels of precision that are essential in the production of tufting parts. These machines are programmed to follow exact specifications, reducing human error and increasing efficiency. The precision machining process not only enhances the quality of the finished product but also optimizes production time and cost.

The Role of Precision Machining in Tufting Parts Production

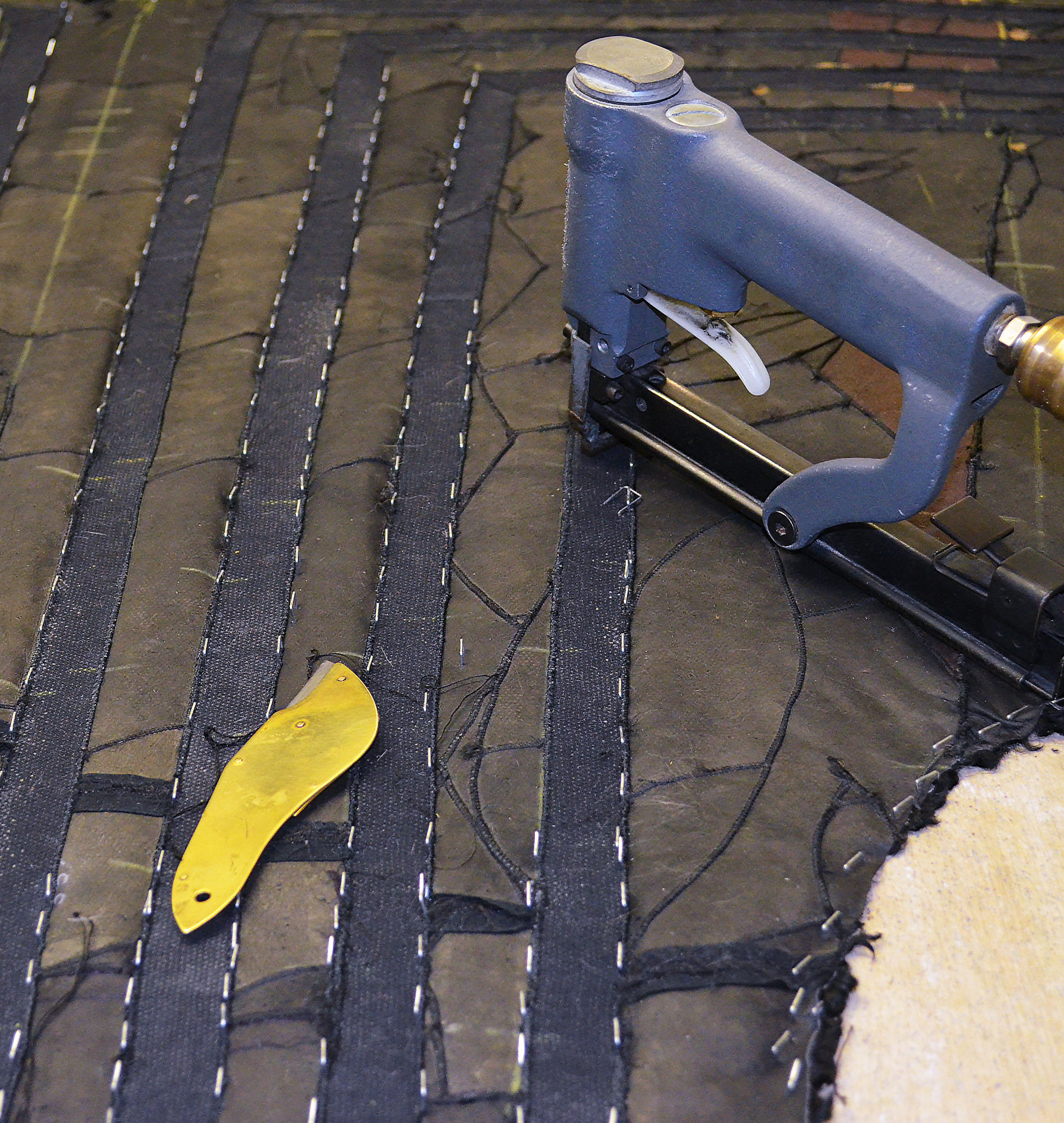

Tufting is a textile manufacturing technique used to create structures like carpets and upholstery. The machinery involved in tufting requires components that need to be precisely machined to ensure smooth operation. Precision machining supports the production of parts such as needles, loopers, and knives, which are integral to the tufting process.

These components must adhere to stringent specifications as even minor deviations can result in significant operational inefficiencies or product defects. Precision machining ensures that each part is crafted with exacting standards, contributing to the overall effectiveness and reliability of tufting machinery.

Benefits of Using Precision Machining for Tufting Parts

One of the primary benefits of precision machining in tufting parts production is the consistency it provides. Every part can be reproduced with the same dimensions and tolerances, leading to uniformity in the final product. This consistency is especially important in large-scale manufacturing where any variation can lead to costly issues.

Moreover, precision machining enhances the durability and performance of tufting parts. By using high-quality materials and precise techniques, manufacturers can produce parts that withstand the rigors of constant use, reducing downtime and maintenance costs.

Technological Advancements in Precision Machining

Advancements in CNC technology have revolutionized precision machining, making it more efficient and accessible. Modern CNC machines are equipped with sophisticated software that allows for complex geometric designs and intricate patterns, which are often required in tufting parts production.

Additionally, real-time monitoring and feedback systems integrated into CNC machines help maintain quality control throughout the manufacturing process. This ensures that any deviations from the set parameters are quickly addressed, further enhancing the reliability of precision-machined tufting parts.

Conclusion: The Future of Precision Machining in Tufting

As technology continues to evolve, precision machining will undoubtedly play an even more significant role in tufting parts production. The demand for high-quality, durable components will drive further innovations in machining techniques and equipment. For manufacturers, staying at the forefront of these advancements will be crucial to maintaining competitiveness in the textile industry.

In conclusion, precision machining is not just a method but a vital component of modern manufacturing that supports the efficient and reliable production of tufting parts. As industries continue to push for higher standards and better performance, precision machining will remain a cornerstone of quality and innovation.