Innovative Trends in Machine Shops: What Dalton Businesses Need to Know

Understanding the Shift in Machine Shop Dynamics

In recent years, the landscape of machine shops has evolved significantly, driven by technological advancements and innovative trends. For businesses in Dalton, staying informed about these changes is crucial for maintaining a competitive edge. The integration of new technologies not only enhances productivity but also offers a pathway to more efficient operations.

One of the most noteworthy trends is the adoption of automation and robotics. Machine shops are increasingly leveraging automated systems to handle repetitive tasks, allowing skilled workers to focus on more complex operations. This shift not only improves accuracy but also reduces the likelihood of human error.

The Rise of Smart Manufacturing

Smart manufacturing is another trend that is reshaping machine shop operations. By utilizing the Internet of Things (IoT), machine shops can now connect machinery and equipment to a central network, enabling real-time monitoring and data analysis. This connectivity allows for predictive maintenance, which minimizes downtime and maximizes productivity.

In addition to IoT, advanced software solutions play a pivotal role in smart manufacturing. These tools offer capabilities such as computer-aided design (CAD) and computer-aided manufacturing (CAM), which streamline the product development process. As a result, businesses can achieve faster turnaround times and bring products to market more quickly.

Embracing Additive Manufacturing

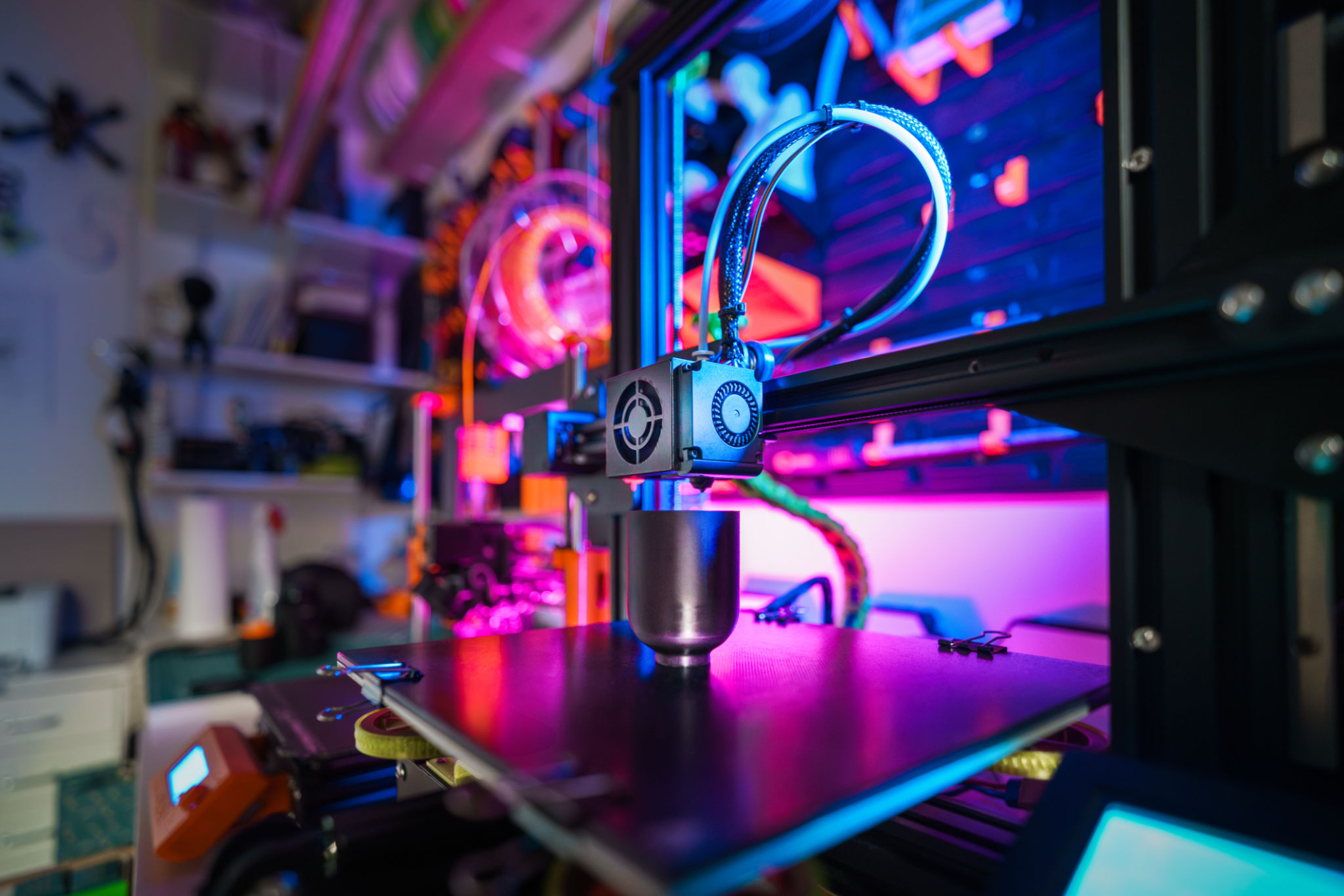

Additive manufacturing, commonly known as 3D printing, is revolutionizing the way machine shops operate. This technology allows for the creation of complex parts and prototypes with unprecedented precision and speed. For Dalton-based businesses, incorporating 3D printing can significantly reduce material waste and lower production costs.

Moreover, additive manufacturing provides greater flexibility in design, enabling customizations that were previously impractical or impossible with traditional methods. This capability can be particularly advantageous for businesses looking to offer tailored solutions to their clients.

Sustainability in Machine Shops

Sustainability is becoming an increasingly important consideration for machine shops. By adopting environmentally friendly practices, businesses can reduce their carbon footprint and appeal to eco-conscious consumers. Implementing energy-efficient machinery and recycling programs are just a few ways machine shops can contribute to sustainability.

Furthermore, sustainable practices often lead to cost savings in the long run. By optimizing resource usage and minimizing waste, machine shops can improve their bottom line while supporting environmental goals.

The Importance of Workforce Development

As technology continues to evolve, so does the need for a skilled workforce. Investing in employee training and development is essential for machine shops aiming to capitalize on emerging trends. Businesses in Dalton should focus on upskilling their workforce to keep pace with technological advancements.

Offering training programs and workshops can help employees acquire new skills and stay updated on industry best practices. This approach not only enhances workforce competency but also boosts employee morale and retention.

Conclusion: Staying Ahead of the Curve

The machine shop industry is undergoing significant transformation due to innovative trends. For Dalton businesses, staying informed and adapting to these changes is vital for continued success. By embracing automation, smart manufacturing, additive technologies, sustainability, and workforce development, machine shops can enhance their operations and remain competitive in an ever-evolving market.

As these trends continue to shape the industry, businesses that proactively adapt are likely to reap substantial benefits. By staying ahead of the curve, Dalton's machine shops can secure their position as industry leaders.