Expert Tips for Extending the Lifespan of Your Tufting Equipment

Understanding the Basics of Tufting Equipment Maintenance

To extend the lifespan of your tufting equipment, it's essential to understand its fundamental mechanics. Familiarize yourself with the machine's manual and ensure that you are aware of all the components and their functions. This basic knowledge will help you recognize when something is amiss, allowing for timely intervention.

Regular maintenance checks are crucial. Make it a habit to inspect your tufting equipment before and after use. Look for any signs of wear and tear, such as frayed cables or loose bolts, and address these issues promptly to prevent further damage.

Implementing a Routine Cleaning Schedule

Dirt and debris can accumulate quickly in tufting equipment, affecting its performance and longevity. Develop a routine cleaning schedule to keep your machine in top condition. Use compressed air to blow out any dust or fibers lodged in the machine's crevices.

For more thorough cleaning, disassemble removable parts according to the manufacturer's instructions. Clean each component with appropriate cleaning agents, being careful not to use harsh chemicals that could damage the materials. Regular cleaning prevents buildup that could lead to mechanical failures.

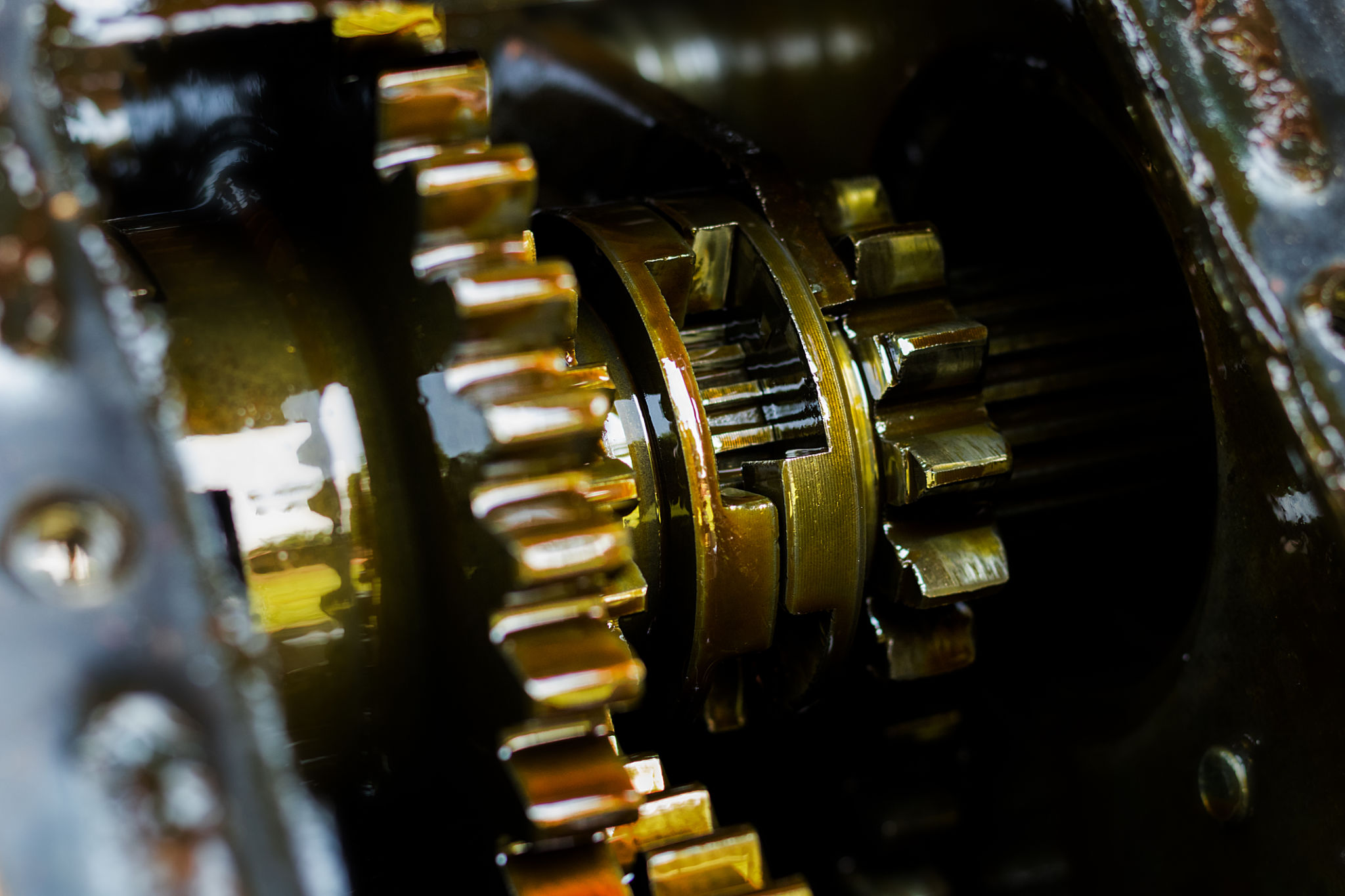

Lubrication: A Key to Smooth Operation

Proper lubrication is essential for reducing friction in moving parts, which can significantly extend the life of your tufting equipment. Follow the manufacturer's guidelines on which lubricants to use and how often. Apply lubrication sparingly to avoid buildup, which can attract dirt and cause blockages.

Training and Skill Development

Ensuring that anyone operating the tufting equipment is well-trained can dramatically reduce the risk of misuse and subsequent damage. Invest in training sessions for new users and refresher courses for experienced operators to keep skills sharp and up-to-date.

Encourage operators to stay informed about new techniques or updates related to your specific equipment model. This knowledge not only enhances efficiency but also contributes to the longevity of the machine by reducing errors in operation.

Keeping an Inventory of Spare Parts

Having an inventory of essential spare parts on hand can save time and reduce downtime in case of a malfunction. Stock up on commonly replaced items such as needles, belts, and bobbins. This proactive approach ensures that minor issues can be addressed swiftly, maintaining productivity.

Regular Professional Servicing

While routine maintenance can be handled in-house, it's vital to schedule regular professional servicing for your tufting equipment. Experts can identify potential issues that may not be apparent during regular checks. Professional servicing ensures that your machine remains in optimal condition and operates safely.

Adhering to a service schedule as recommended by the manufacturer can prevent costly repairs in the long run. Trusting professionals for periodic maintenance is a worthwhile investment in your equipment's lifespan.

Adapting to Technological Advancements

The tufting industry is constantly evolving with new technologies and equipment upgrades. Stay informed about these advancements as they can offer solutions that improve efficiency and extend the life of your current machinery. Consider upgrading components or software when beneficial, as this can enhance performance without needing a complete replacement.

By following these expert tips, you can maximize the lifespan of your tufting equipment, ensuring it remains a valuable asset for years to come. Regular care, proper training, and staying informed about industry developments are key strategies for maintaining your investment.