DIY Maintenance Tips for Tufting Machines: Keep Your Equipment Running Smoothly

Introduction to Tufting Machine Maintenance

Tufting machines are powerful tools that bring creativity to life by allowing you to create intricate patterns and textures. However, like any other piece of equipment, they require regular maintenance to function optimally. Keeping your tufting machine well-maintained not only ensures smooth operation but also extends its lifespan.

Regular Cleaning

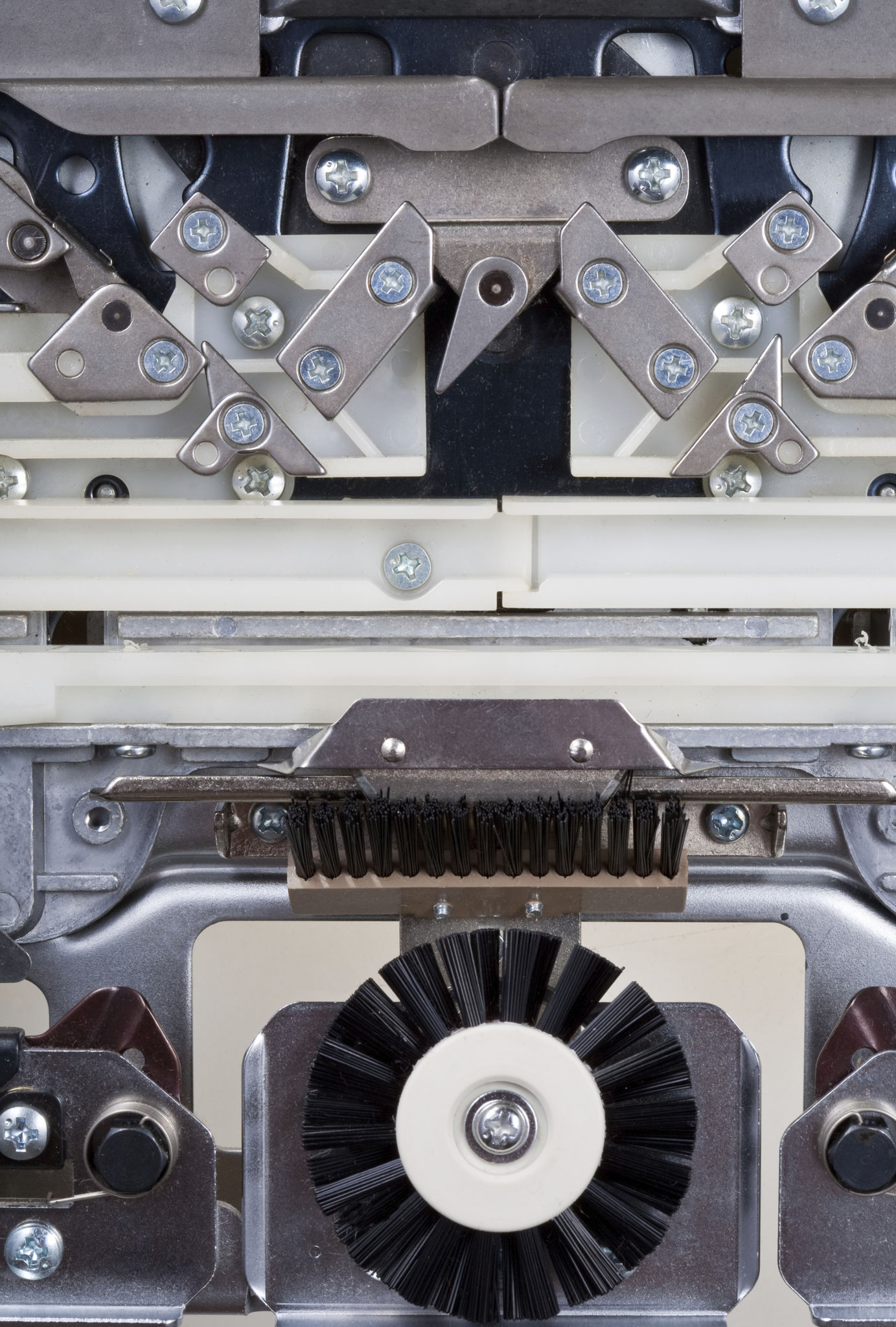

One of the most important aspects of maintaining your tufting machine is regular cleaning. Dust, lint, and other debris can accumulate in the machine, causing it to jam or function inefficiently. It's recommended to clean your machine after each use by using a soft brush or compressed air to remove any unwanted particles.

Lubrication

Lubrication is essential for keeping the moving parts of your tufting machine in good condition. Over time, friction can lead to wear and tear. Use a manufacturer-recommended lubricant to oil the necessary components of your machine. This should be done every few weeks or according to the frequency of use, ensuring that all moving parts are smoothly operational.

Checking for Wear and Tear

Regularly inspect your tufting machine for signs of wear and tear. Pay close attention to the needles and hooks as these parts are prone to damage. Replace any worn or damaged components immediately to avoid further issues or potential safety hazards.

Tension Adjustment

Proper tension adjustment is critical for achieving high-quality tufting results. If you notice loops or irregularities in your work, it might be time to adjust the tension settings. Refer to your machine’s manual for guidance on adjusting tension correctly, ensuring that your fabric is held firmly in place during operation.

Electrical Components Check

Periodically check the electrical components of your tufting machine. Ensure that all wires are intact and there are no loose connections. This not only helps in maintaining performance but also prevents potential electrical hazards. If you're not confident in handling electrical components, consider hiring a professional technician for a thorough inspection.

Storage Considerations

When your tufting machine is not in use, store it in a clean, dry place away from direct sunlight and moisture. Cover the machine with a dust cover to protect it from environmental factors that could cause damage over time. Proper storage practices will help maintain your machine’s condition during periods of inactivity.

Conclusion

Maintaining your tufting machine doesn't have to be a daunting task. By incorporating these DIY maintenance tips into your routine, you can ensure that your tufting machine remains in top working condition. Regular maintenance not only enhances performance but also prolongs the life of your equipment, allowing you to continue creating stunning projects.